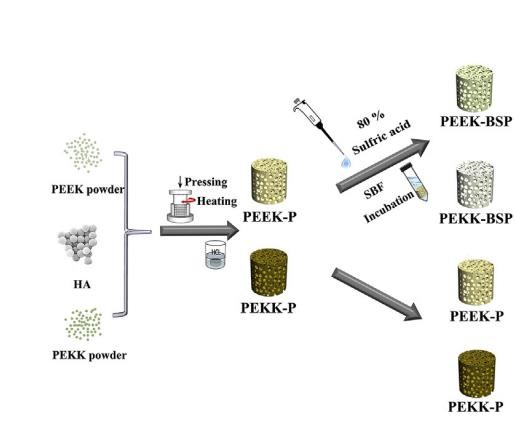

聚芳基醚酮(PAEK)是一种高温热塑性聚合物,由于其良好的生物相容性,较高的机械强度和射线不透性,现已逐渐成为骨科和创伤领域的主要聚合物材料。已经进行了许多工作来改善PEEK的骨整合特性。 使用了三种主要策略,包括具有生物活性填充剂的复合材料,通过物理或化学方法进行的表面改性以及内置有三维多孔结构的支架。

四川大学国家生物材料工程技术研究中心张兴栋院士团队报道发现聚醚酮酮(PEKK)是PAEK的另一种代表性材料,近年来越来越多地被报道为有前途的骨科材料。 PEKK现在已逐渐用于生物医学应用。除了具有更高的热稳定性和机械强度外,PEKK还具有更多的酮基,与PEEK相比,可以提供更多的表面化学改性选择。

Polyaryletherketone (PAEK), a family of high temperature thermoplastic polymer, has now gradually become the leading polymer material in the fifields of orthopedics and trauma, due to its good biocompatibility, high mechanical strength and radiolucency. Much work has been conducted to improve the osteointegration property of PEEK. Three main strategies including composites with bioactive fifillers, surface modifification with either physical or chemical methods, and the scaffolds with build-in of three-dimensionally porous structures were utilized. Polyetherketoneketone (PEKK), another representative PAEK material, has been increasingly reported as a promising orthopedic material in recent years. PEKK has now been gradually used for biomedical application. Besides higher thermostability and mechanical strength, PEKK has more ketone groups and could allow more choices of surface chemical modifification than PEEK..

DOI: 10.1016/j.biomaterials.2018.04.014

李昊宇