Wang et al. / Biomaterials 171 (2018) 118—132

Wang et al. / Biomaterials 171 (2018) 118—132

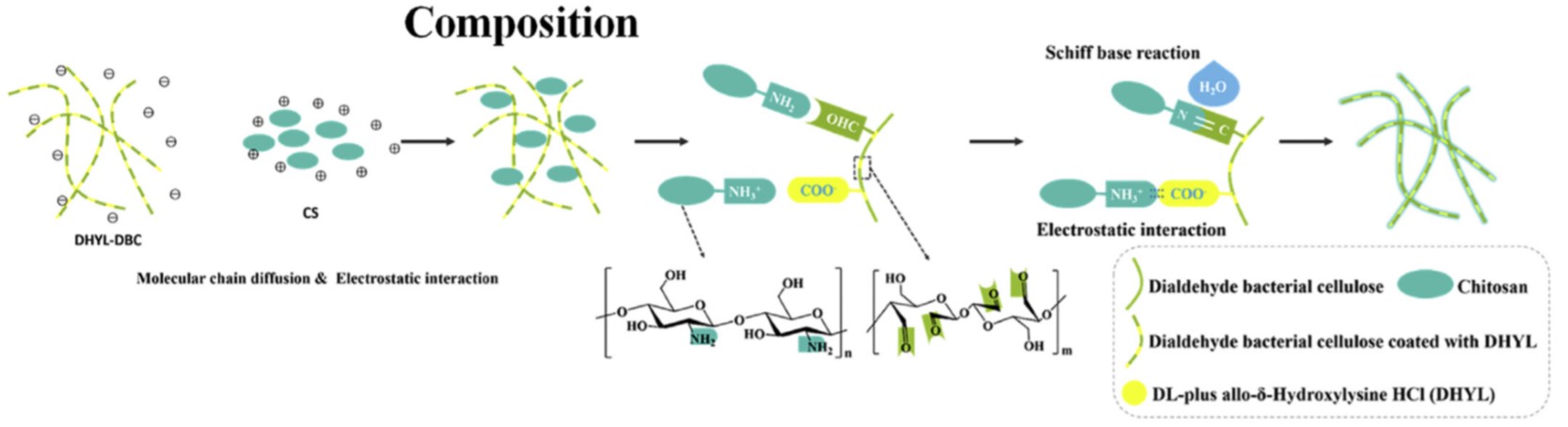

微载体是一种可注射的灵活性高的组织工程材料,微载体通常有合成材料微载体与天然材料微载体。其中天然材料微载体由于更为贴合人体内部生长环境,被广泛利用。但诸如壳聚糖、胶原类微载体存在着力学强度较低,降解速率快,且存在潜在的免疫原性,限制了其体内应用。本文开发了一种化学法模拟细胞外基质(ECM)的纳米纤维微载体,用于体内软骨修复,作者利用高碘酸钠氧化细菌纤维素得到二醛化细菌纤维素(DBC),再与羟化赖氨酸(DHYL)发生席夫碱反应键连,最终通过席夫碱反应与静电吸附作用和壳聚糖共同形成微载体结构,并通过种植骨髓间充质干细胞(BMSCs),在微重力旋转细胞培养系统(RCCS)中增殖分化,得到软骨细胞微组织。经过力学评估,体外降解实验,免疫荧光染色等表征,证明改性后的纳米纤维微载体具有良好的力学强度,缓慢的降解速率,优异的细胞活性,是软骨修复的有利材料,微组织结构更是值得临床研究的潜在目标。

北京科技大学的郑裕东教授本科和硕士毕业于北京航空航天大学;获华南理工大学高分子材料学博士学位。1993年-2004年在华南理工大学材料学院工作,主要从事生物材料和功能高分子复合材料的研究与开发。2004年在北京科技大学生物材料研究室工作,2011年,2013年赴英国进行访学和国际项目合作交流。主要开展了生物医用水凝胶植入材料、生物相容性导电水凝胶、纳米生物复合材料制备与表征,及其在皮肤、软骨、神经修复等医学领域的应用等研究。

Microcarrier is an injectable tissue engineering material with high flexibility. Microcarriers usually include polymer material microcarriers and natural material microcarriers. Among them, the natural material microcarriers are widely used because they are more suitable for the internal growth environment of the human body. However, microcarriers such as chitosan and collagen have low mechanical strength, fast degradation rate, and potential immunogenicity, which limits their applications in vivo. This article developed a chemical method to simulate the extracellular matrix (ECM) of nanofiber microcarriers for cartilage repair. The authors used sodium periodate to oxidize bacterial cellulose to obtain dialdehyde bacterial cellulose (DBC), and then combine hydroxyl The lysine (DHYL) through Schiff base reaction, finally forms a microcarrier structure through the Schiff base reaction and electrostatic adsorption with chitosan, and is implanted with bone marrow mesenchymal stem cells (BMSCs) under microgravity proliferation and differentiation in a rotating cell culture system (RCCS) to obtain chondrocyte microtissues. After mechanical evaluation, degradation experiments in vitro, immunofluorescence staining and other characteristics, it proves that the modified nanofiber microcarriers have good mechanical strength, slow degradation rate, and excellent cell activity. They are an advantageous material for cartilage repair, and the microstructure is more It is a potential target worth clinical research.

Professor Zheng Yudong of Beijing University of Science and Technology graduated from Beijing University of Aeronautics and Astronautics with a bachelor’s and master’s degree; he obtained a Ph.D. in polymer materials from South China University of Technology. Worked in the School of Materials Science and Engineering of South China University of Technology from 1993 to 2004, mainly engaged in the research and development of biomaterials and functional polymer composites. In 2004, he worked in the Biomaterials Laboratory of the University of Science and Technology Beijing. In 2011 and 2013, he went to the UK for study visits and international project cooperation and exchanges. Mainly carried out the preparation and characterization of biomedical hydrogel implant materials, biocompatible conductive hydrogels, nano-biocomposites, and their applications in skin, cartilage, nerve repair and other medical fields. DOI:https://doi.org/10.1016/j.biomaterials.2018.04.033

李建超